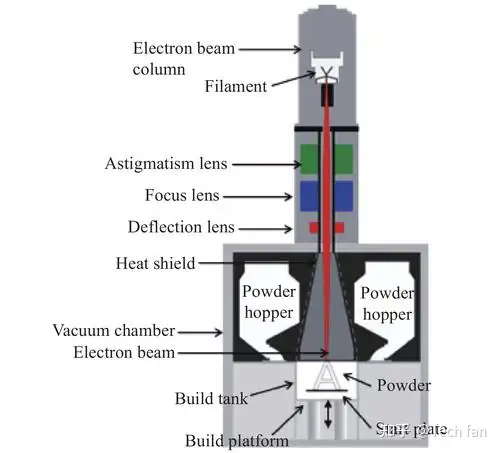

Principle of EBM electron beam melting technology:

Electron Beam Melting technology is an emerging advanced metal rapid prototyping manufacturing technology in recent years. After intensive in-depth research and development, it is now widely used in rapid prototyping, rapid manufacturing, tooling and biomedical engineering and other fields. The principle is to import the three-dimensional solid model data of the part into the EBM equipment, and then lay a thin layer of fine metal powder in the working chamber of the EBM equipment, and use the high-density energy generated by the deflection and focus of the high-energy electron beam to make the object The scanned metal powder layer generates high temperature in local micro areas, causing the metal particles to melt. Continuous scanning of the electron beam will cause the tiny metal molten pools to fuse and solidify with each other, and connect to form linear and planar metal layers.

The electron beam is generated by an electron beam gun located at the top of the vacuum chamber. The electron gun is fixed, while the electron beam can be steered in a controlled manner to reach the entire processing area. Electrons are emitted from a filament, and when the filament is heated to a certain temperature, it emits electrons. Electrons are accelerated to half the speed of light in an electric field. The electron beam is then controlled by two magnetic fields. The first magnetic field acts as an electromagnetic lens and is responsible for focusing the electron beam to the desired diameter. A second magnetic field then steers the focused electron beam to the desired operating point on the bench.

Because of its ability to directly process complex geometric shapes, the EBM process is very suitable for direct mass production of small batches of complex parts. The process makes it possible to customize parts, and parts optimized for the CAD to metal process can achieve geometries that are impossible to form with other manufacturing technologies. Therefore, the parts will demonstrate their value to customers due to unparalleled performance. This process directly uses CAD data and is done in one step, so it is very fast. From the time the designer completes the design, all functional details are available within 24 hours. Using this process, lead times are significantly reduced compared to sand casting or investment casting.

Technical features:

Advantage:

1. Ability to directly process complex geometric shapes, such as cavities, grid structures, etc., with near-net shape and dimensional accuracy of ±0.2mm;

2. The ability to achieve high power on a narrow beam, and the molding efficiency is high, reaching 55~80 cm3/hr. Compared with sand mold casting or investment precision casting, the production cycle is significantly shortened;

3. Vacuum melting eliminates impurities (such as oxides and nitrides) and ensures the high strength of the material;

4. Can smelt refractory metals and fuse different metals;

5. The molding environment temperature is high (above 700°C) and the residual stress of the parts is small;

6. The remaining powder after molding can be recycled and reused.

Insufficient:

1. The molding equipment needs to be equipped with a vacuum system and requires maintenance, which increases the cost;

2. The printing process will produce X-rays (a properly designed vacuum chamber can effectively shield the rays)

EBM technology uses metal powder as raw material, and its application range is quite wide, especially in refractory and difficult-to-process materials, including titanium alloys, titanium-based intermetallic compounds, stainless steel, cobalt-chromium alloys, nickel alloys, etc., and its products can Achieve high levels of complexity and achieve high mechanical properties. This technology can be used in the manufacturing of multi-jointed blades, casings, radiators, supports, lifting lugs and other structures of aerospace vehicles and engines.