Wood, stone, glass, metal, marble... Each material has its own characteristics. Of course, new materials are relatively innovative. Take the new material shared by the editor today - liquid metal. It is also a new attempt, let’s take a look:

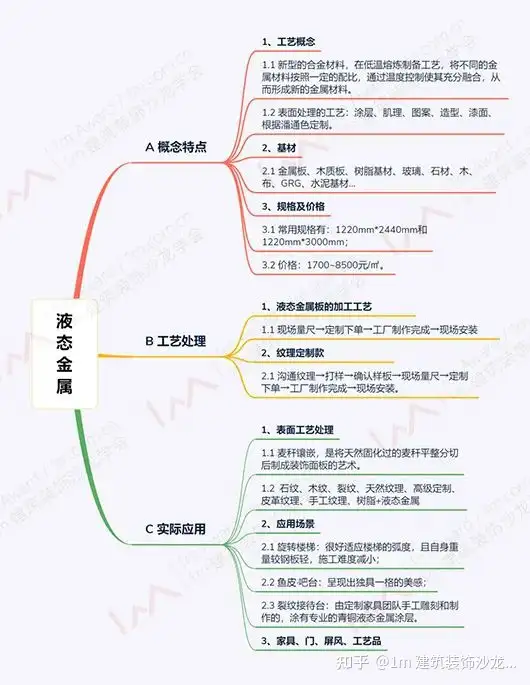

1. What is liquid metal?

2. What is the process like?

3. What are the practical applications of liquid metal?

What is liquid metal?

1. Process concept

Liquid metal is a new type of alloy material. Under the low-temperature smelting preparation process, different metal materials are fully fused according to a certain ratio and controlled by temperature to form a new metal material (which can also be understood as surface treatment techniques).

Depending on the material ratio, the liquid metal material formed will also have different functional properties. This technology, which can perfectly integrate resin and metal powder, can be used in aerospace and is also considered a black technology.

a. Surface treatment process

It can present a pure metallic texture on various substrates and achieve seamless closing of any shape.

Surface treatment processes include: coating, texture, pattern, shape, paint surface, and customized color matching standards based on Pantone color standards.

b. Personalized customization

It can be combined with 3D printing technology, sculptures, furniture, and lighting to realize innovative applications of personalized decoration and truly realize personalized customization needs.

2.Substrate

Liquid metal is used in a wide range of scenarios, such as: furniture, sculptures, artworks, doors, ceilings, walls, screens and partitions, props exhibitions, LOGO, lighting, spiral staircases, cement columns, GRG... It can be seen from this , it is applicable to many substrates.

a. Metal plates: aluminum plates, stainless steel plates, iron plates, etc.

b. Wooden board: MDF board, multi-layer plywood

c. Resin base material: petg, acrylic, 3D printing resin

d. Glass: car-engraved glass, etched glass

e. Stone: artificial stone, natural stone

f. Wood: density board, multi-layer board, solid wood

g. Cloth: canvas, wall covering

h, GRG: fiberglass, polyurethane

i. Cement base material: cement columns, cement walls

According to the design texture, you can combine mold turning, stamping, scraping, post-polishing and other processes to achieve the desired texture.

3.Specifications and prices

a、Specifications

According to the base plate, there are various specifications. Common specifications are: 1220mm*2440mm and 1220mm*3000mm (partial) and some special shapes.

b、Price

The price is about 1,700~8,500 yuan/square meter, and the price varies according to different styles and special customization requirements.

相Compared with pure copper, the price is lower and the weight can be reduced. Customized textures are highly malleable, seamless, delicate and clear.

4

Features

a. Fire resistance

Fire resistance varies depending on the substrate. For example, the fire resistance of the liquid metal surface layer + aluminum composite panel can reach Class A, which can meet the different requirements of high-rise buildings and various commercial spaces.

b. Environmental protection

The material is ecological and environmentally friendly, formaldehyde-free and solvent-free. It has excellent outdoor UV resistance and is not prone to discoloration.

c. Various colors

The color can be bronze, antique copper, brass, red copper, gold, silver, retro, etc.

What is the installation process like?

The installation process mentioned here actually depends on the base plate to which the liquid metal is attached. If the base plate is different, the installation process will of course be different.

Let’s first talk about the processing technology of liquid metal plates, which are usually customized by the factory. The general process is: on-site measurement → custom order → factory production completed → on-site installation.

Let’s first talk about the processing technology of liquid metal plates, which are usually customized by the factory. The general process is: on-site measurement → custom order → factory production completed → on-site installation.

As for the installation process, I will not explain too much here and show you some commonly used plate installation nodes.

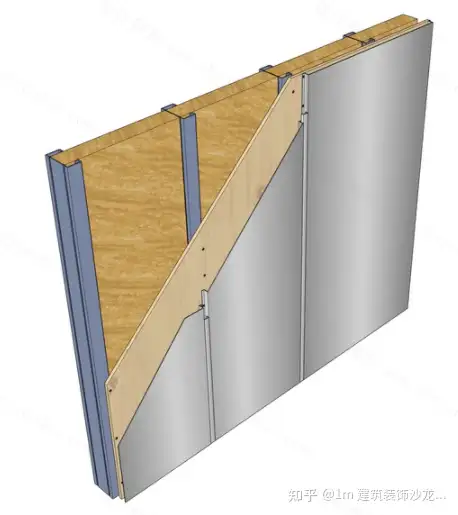

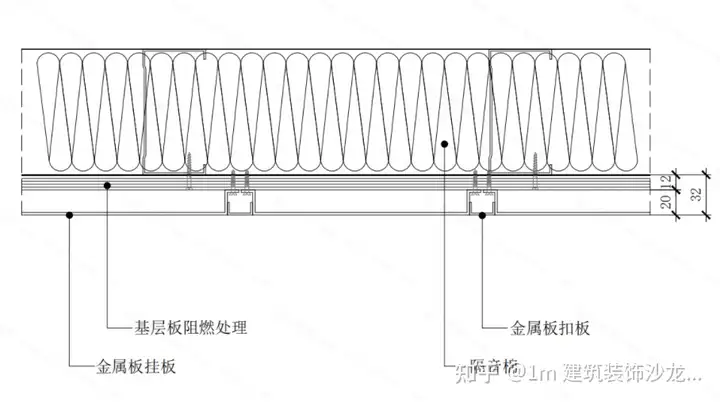

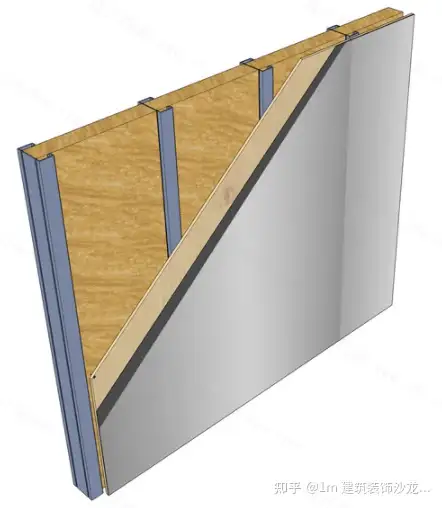

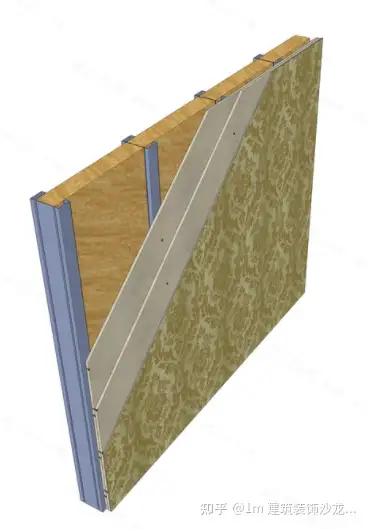

1.Metal

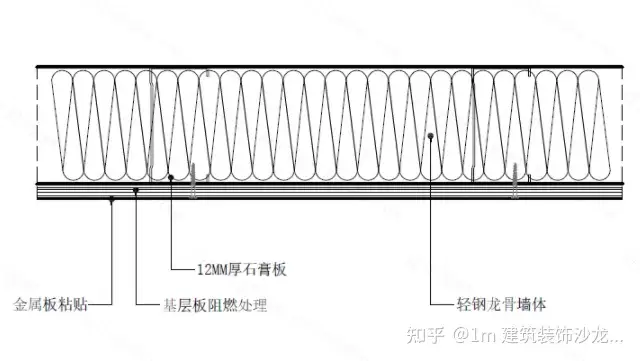

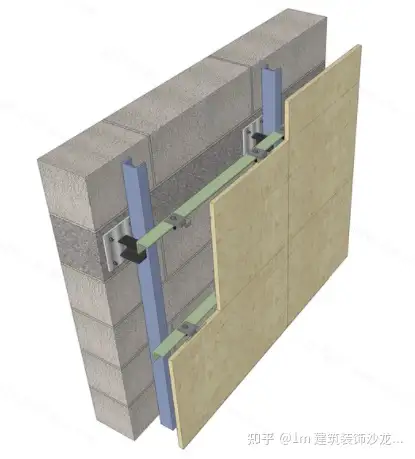

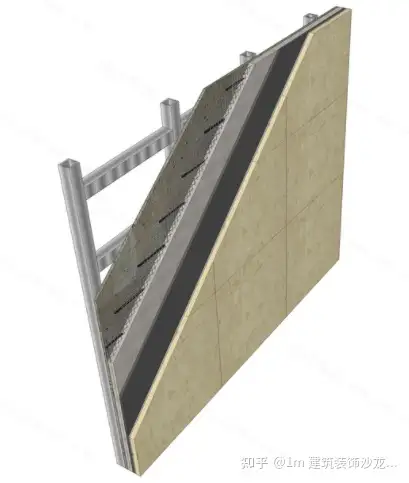

△Metal hanging panel wall node diagram

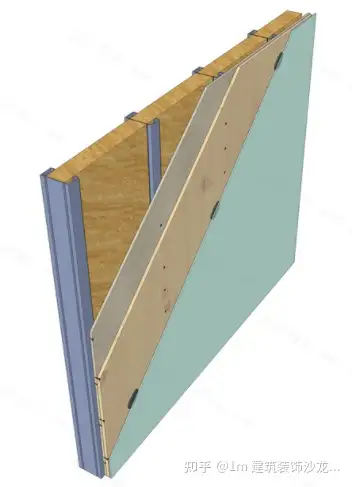

△Metal sheet pasted wall node diagram (light steel keel wall)

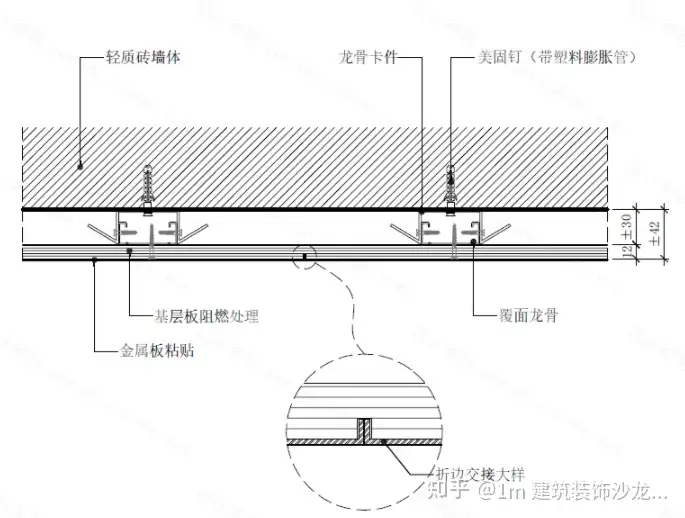

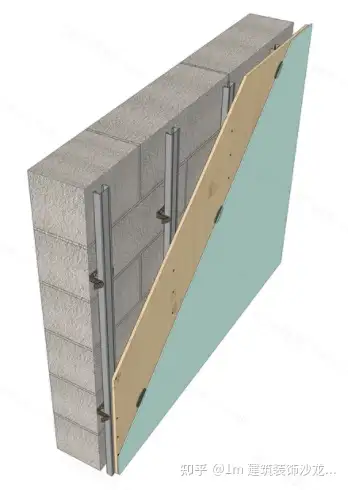

△Metal sheet pasted wall node diagram (lightweight brick wall)

Gluing process: leveling the base layer → priming the blockboard → gluing on the reverse side of the finished metal plate. Structural glue (nail-free glue) is placed 5cm away from the edge of the board. Glue in dots with a dot spacing of 10~15cm. Paste → Details Process → Complete.Gluing process: leveling the base layer → priming the blockboard → gluing on the reverse side of the finished metal plate. Structural glue (nail-free glue) is placed 5cm away from the edge of the board. Glue in dots with a dot spacing of 10~15cm. Paste → Details Process → Complete.

2.Wood veneer

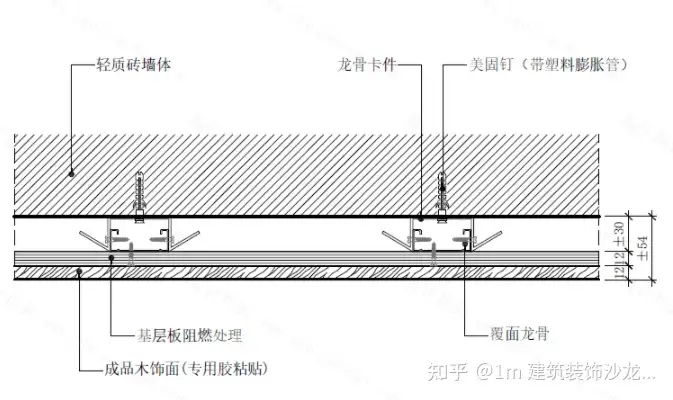

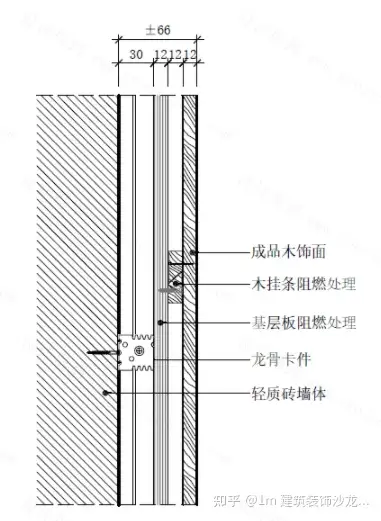

△△Node diagram of wood veneer pasted wall (lightweight brick wall)

△Wood veneer wall node diagram (longitudinal section) (lightweight brick wall)

3.Glass

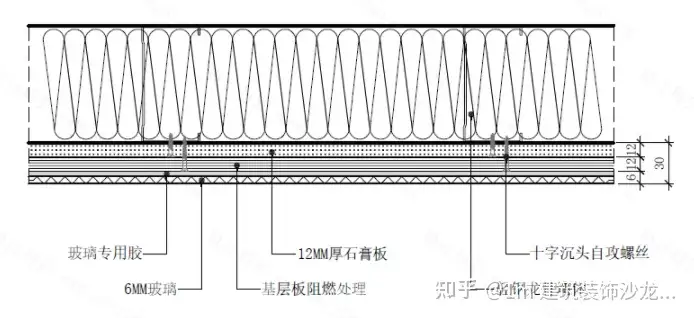

△Glass facing wall node diagram (light steel keel wall)

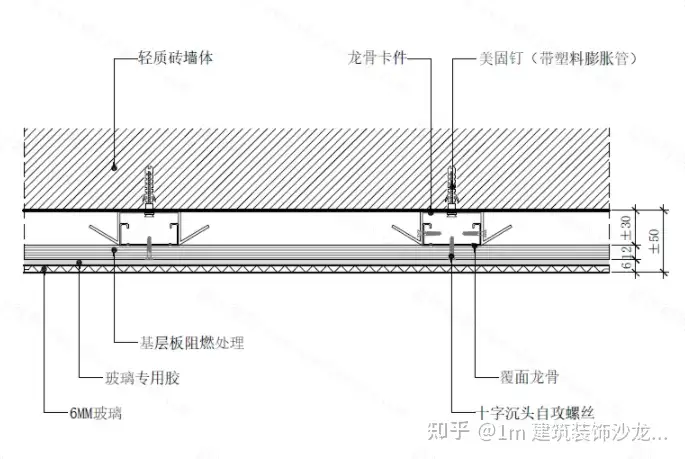

△Glass facing wall node diagram (lightweight brick wall)

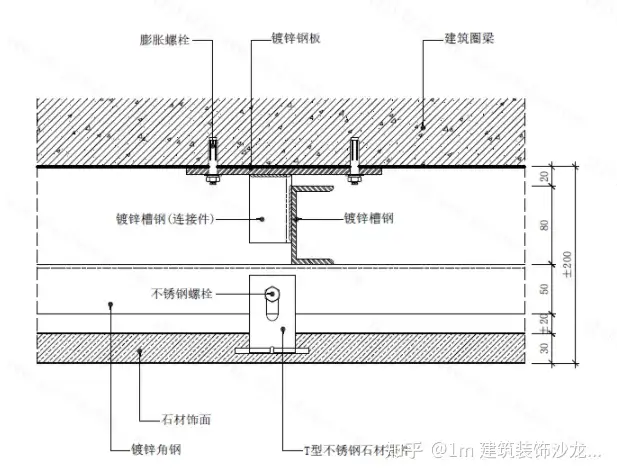

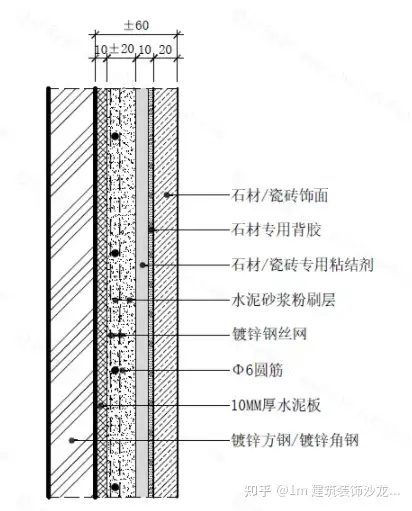

4.Stone

△Stone dry hanging wall node diagram

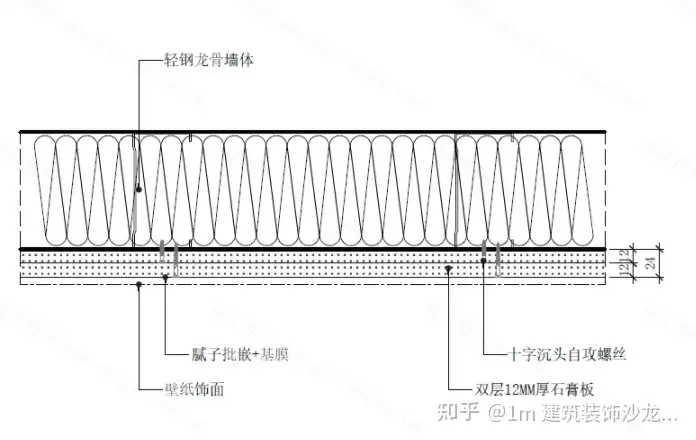

5.Wallpaper

△Wallpaper facing wall node diagram

Practical application

Now that we know that liquid metal is actually a finishing process, and its installation is based on the base material, what is its practical application?

Next, let’s take a look at its specific effects through specific process processing and some application scenarios:

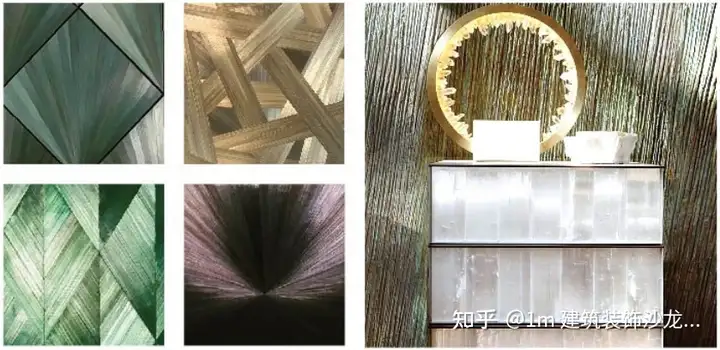

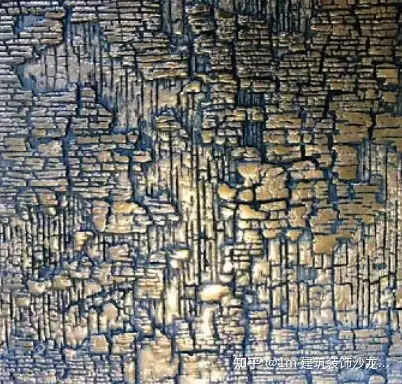

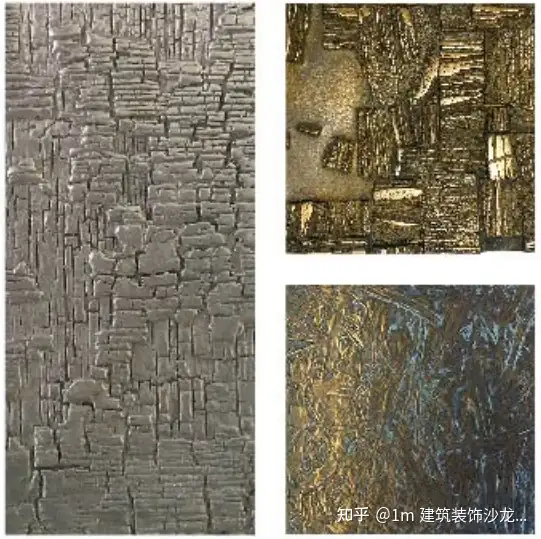

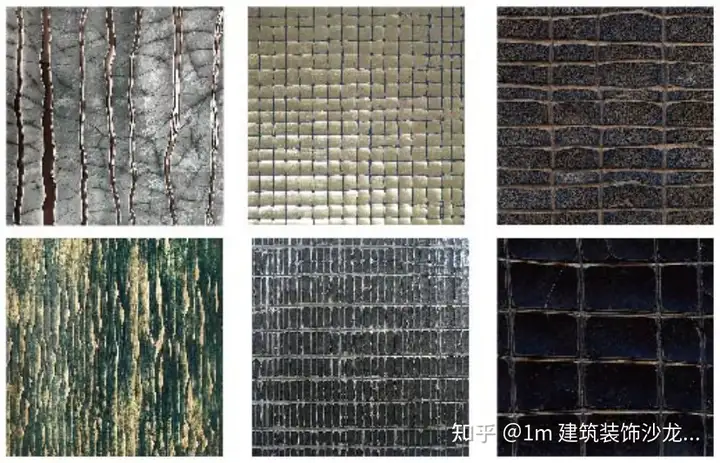

1.Surface treatment

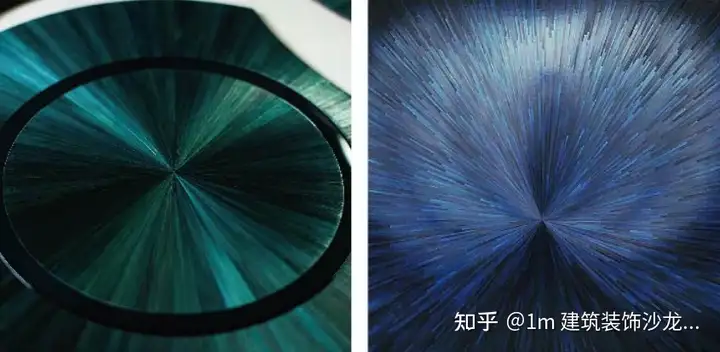

a、Wheat straw technology

Wheat straw inlay is an artistic process in which natural solidified wheat straw is cut into flat pieces and then made into decorative panels.

Combining this process with liquid metal, the finished product not only exudes a gem-like luster on its own surface, but also allows light and external colors to refract and change on its surface to create an unparalleled brilliance.

b、Wood grain

△Wood grain

c、Stone pattern

d、Cracks

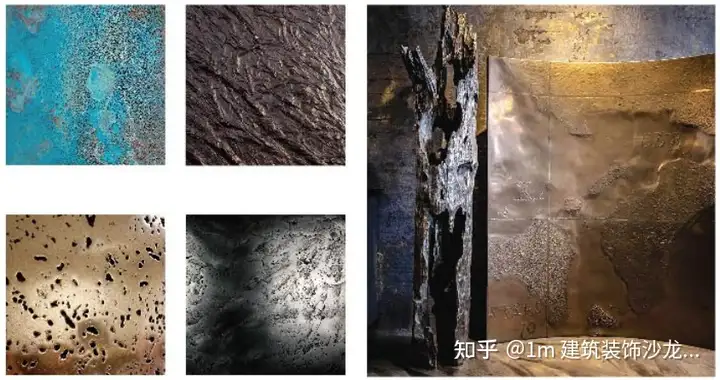

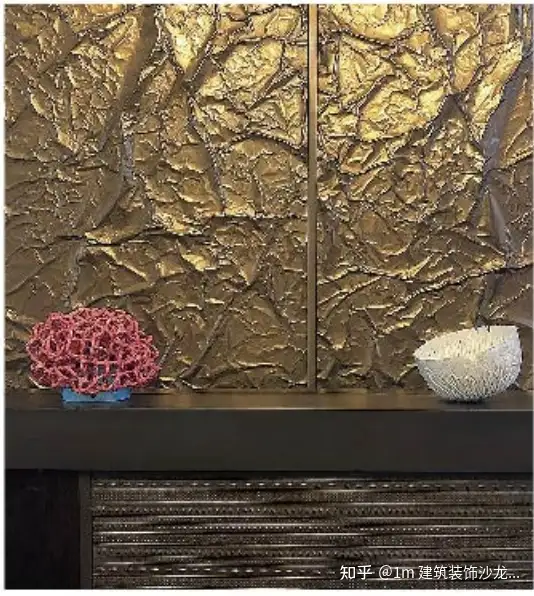

e、Natural texture

f、Advanced customization

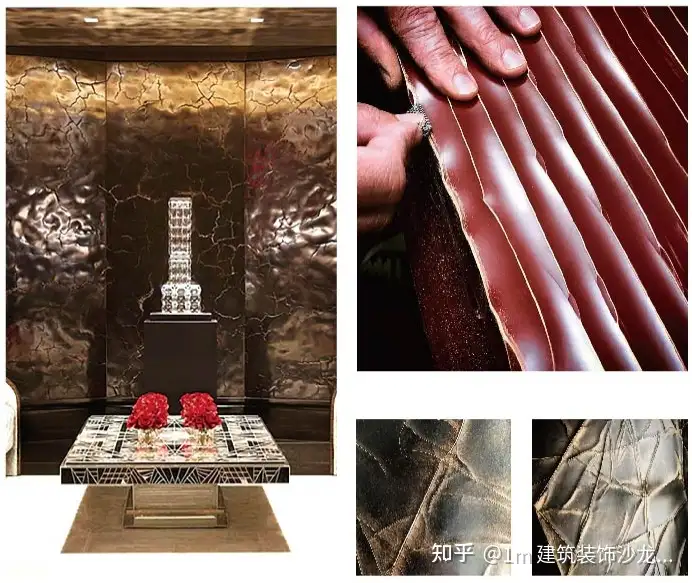

g、Leather texture

h、Handmade texture

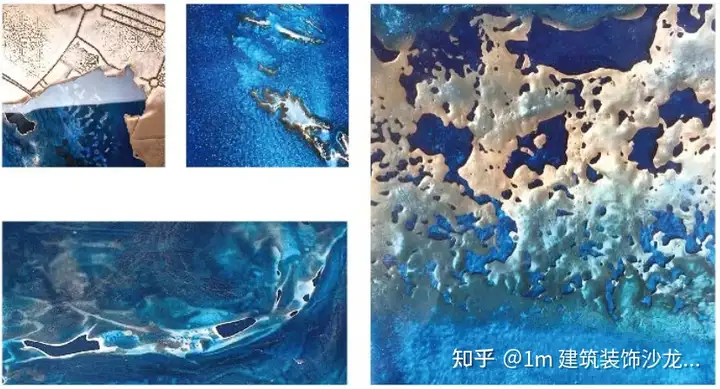

i、Resin + liquid metal

Resin, wood, and liquid metal are combined to achieve customized walls.

△Resin and copper combination

The combination of liquid metal and resin complements each other, and the oxidation of the liquid metal is protected by the resin; when the resin is poured into the shape of the liquid metal, the transparent resin echoes the texture of the liquid metal, forming a contrasting beauty and a different kind of harmony.

2.Application scenarios

a、Liquid metal·spiral staircase

The spiral staircase is made of liquid metal. The liquid metal perfectly fits the curvature of the staircase, and its weight is lighter than the steel plate, which reduces the difficulty of construction.

b、Liquid metal fish skin·Bar counter

Pearlfish skin liquid metal presents a unique aesthetic, a perfect combination of classic and innovative.

c、Crack reception desk

△Hand-carved and crafted by the custom furniture team

Coated with a professional bronze liquid metal coating

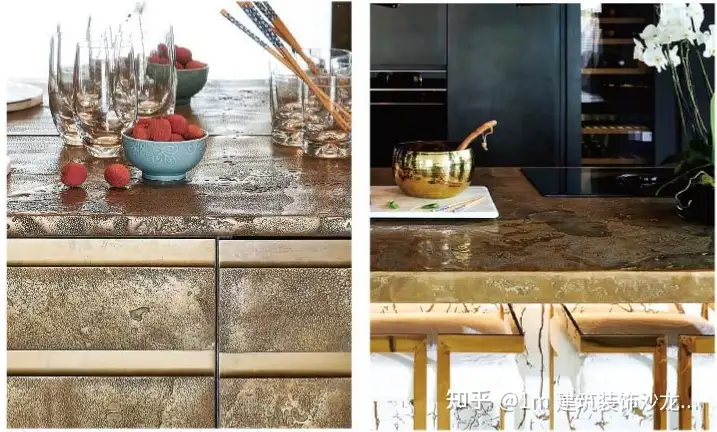

3.Furniture application

Metal table

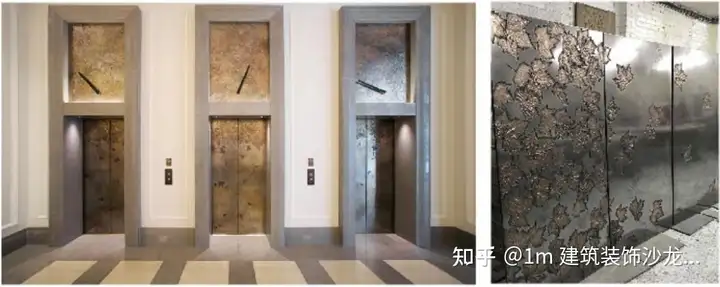

4.Doors, screens, handicrafts

a、Door

△Supports various geometric pattern design customizations

3D printing & relief processing into shapes

b、Handicrafts

Use liquid metal to reshape the shape of the human body and add a unique sparkle to your private space with artwork made of liquid metal.

c、Handicrafts

Summary

This concludes the introduction to liquid metal. Today we mainly understand its characteristics and specific application effects. As for the installation process, it still depends on the base material before determining it.

Finally, let’s summarize today’s content: